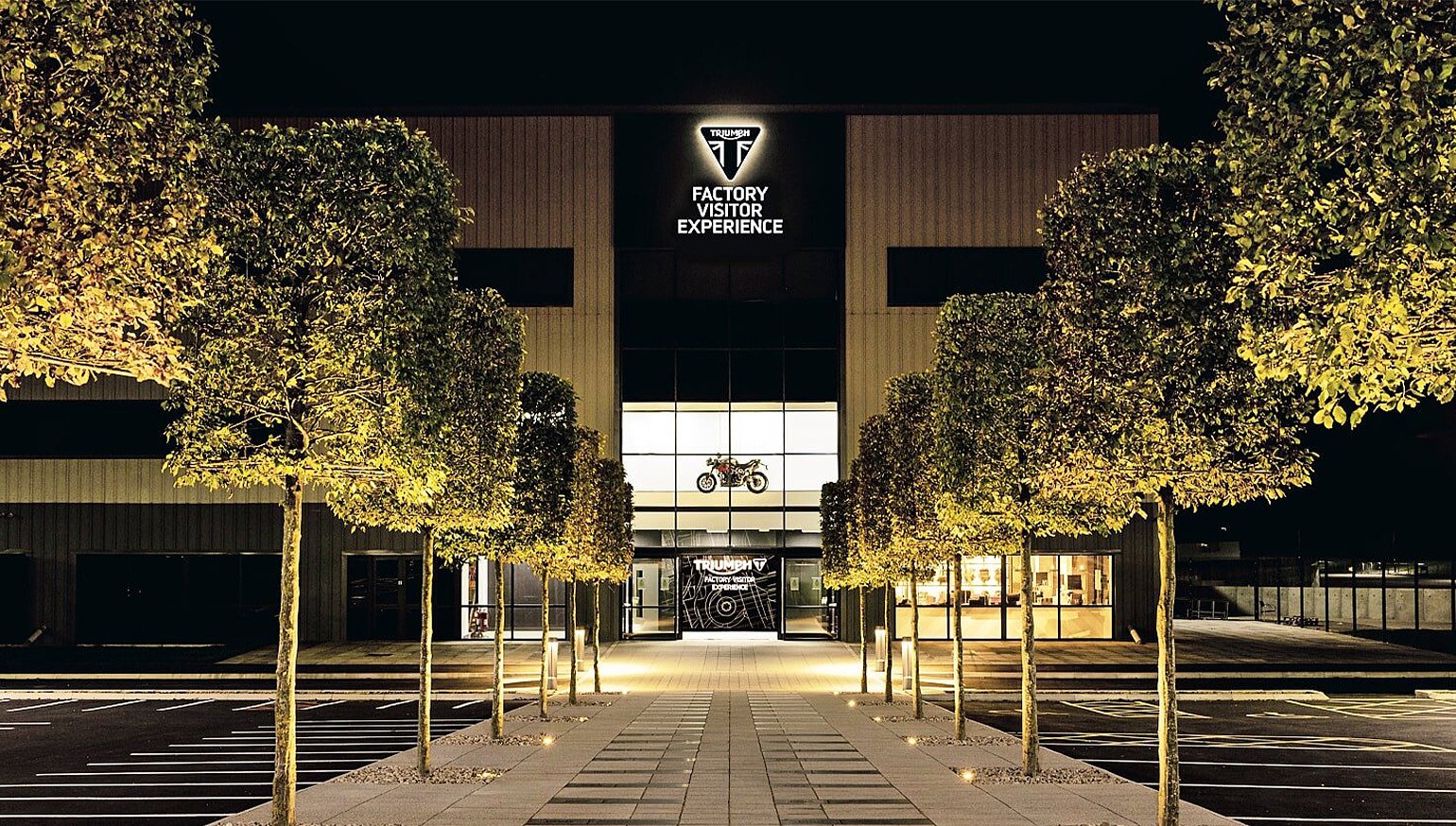

Wheat and barley fields stretch as far as the eye can see. Sheep, cattle, and Shetland ponies dot this sea of green and gold. Age-old hamlets line roads so old they’re still called carriageways. This pastoral scene of the English countryside streams past the charter bus windows. That is until Triumph’s factory and headquarters in the town of Hinckley come into view.

We pile out of the coach, still buzzing from the TR Series launch the evening before. The British OEM’s Moto2 prototype greets visitors as they enter through the 1902 Café. The café itself looks transported from a trendy Soho neighborhood, except for the landmark Triumph engines decorating the back wall, of course.

With my factory tour scheduled later in the day, I mosey through the adjoining exhibits. The free time allows me to gawk at Steve McQueen’s TR6 from “The Great Escape,” Tom Cruise’s “Mission: Impossible 2” Speed Triple 955i, and the Scrambler 1200 ridden by Daniel Craig in “No Time to Die.”

From the first T120 to roll off the assembly line in 1958 to Peter Hickman’s Isle of Man TT podium-standing Daytona 675R, the quasi-museum tells the tale of Triumph's decorated past. I’m more concerned with its present and future, though, and those details lie beyond the production plant’s closely guarded doors.

Behind the curtain

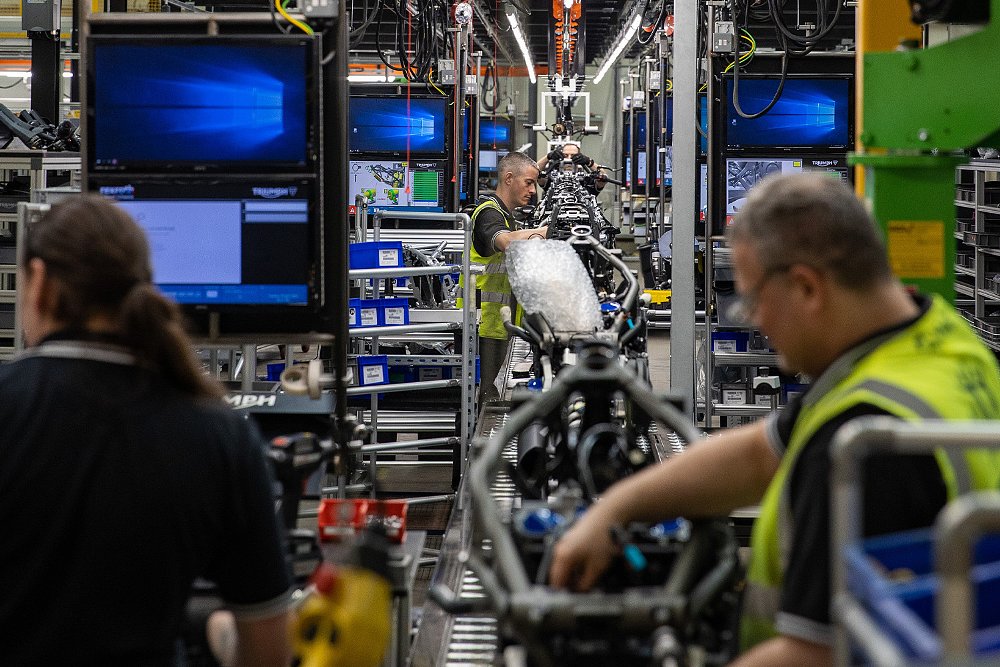

With those same doors shut securely behind our group of 10 to 12 journalists, the tour guide covers the first, and most important, rule: no photography. After all, Triumph has several projects currently in development. Giving the public a peek behind the curtain can’t come at the expense of guarding those secrets. No, I didn’t catch a glimpse of the brand’s upcoming dirt bikes, but the tour revealed other details about Triumph’s inner workings.

Admittedly, much of the tour centered on statistics and production quotas. I, on the other hand, cared less about the X number of crankshafts shipped weekly or the Y pounds spent on the state-of-the-art paint facility (it’s £4 million, by the way). What was fascinating to me was the paint booth’s waterfall back wall, which captures errant paint to be filtered out by Triumph’s advanced processing system.

The paint department doesn’t depend on high-tech solutions alone. Triumph’s special-edition Gold Line series favors the old-school approach, employing hand-laid pinstriping to fan-favorite models. Only two pinstripers — Natasha and Gad — are qualified to apply the gold accents and each adds their John Hancock to every fuel tank completed. During my visit, Natasha was hard at work, painstakingly prepping bodywork for the painting process.

The R&D department offered a different behind-the-scenes look. Triumph utilizes 3D-printed components to help turn a concept into a reality. The built-to-scale Trident 660 on hand put the technology’s capabilities on full display. However, handling individual parts gave me a true appreciation of the detail achieved by 3D printing. Once those prototypes give way to a production model, though, all the action takes place on the assembly line.

Unfortunately, the Hinckley facility was implementing production-line upgrades during the late-June tour. As a result, our group couldn’t witness the production process firsthand. That’s a shame, as I would’ve loved to see Triumph’s intuitive operating system, which calls out the particular fastener, drill, and torque spec for a given part, in action. The same goes for the “Rolling Road,” Triumph’s in-house dynamometer.

Soon after, the tour drew to a conclusion, but not before highlighting John Bloor’s personal collection, a Bonneville ridden by David Beckham, and the firm’s TE-1 electric roadster concept. As I returned my safety vest and headset to the tour guide, I realized just how much the abbreviated tour covered. Yet, I felt like a return trip was still warranted.

Until next time

While my tour lasted approximately 70 minutes, brand reps report that the standard offering runs for one hour and 30 minutes. Considering the Factory Visitor Experience (FVE) starts at just £25 ($32 U.S.), it’s a small price to pay for access to Triumph’s production facility, museum, apparel shop, and café. Those looking for the royal treatment can opt for the Full Works Experience instead, which costs £235 ($302 U.S.) for four people.

Triumph’s Hinckley headquarters may be a technological oasis in rural England, but the FVE doesn’t just hint at the company’s future, it celebrates its rich history, as well.

Membership

Membership