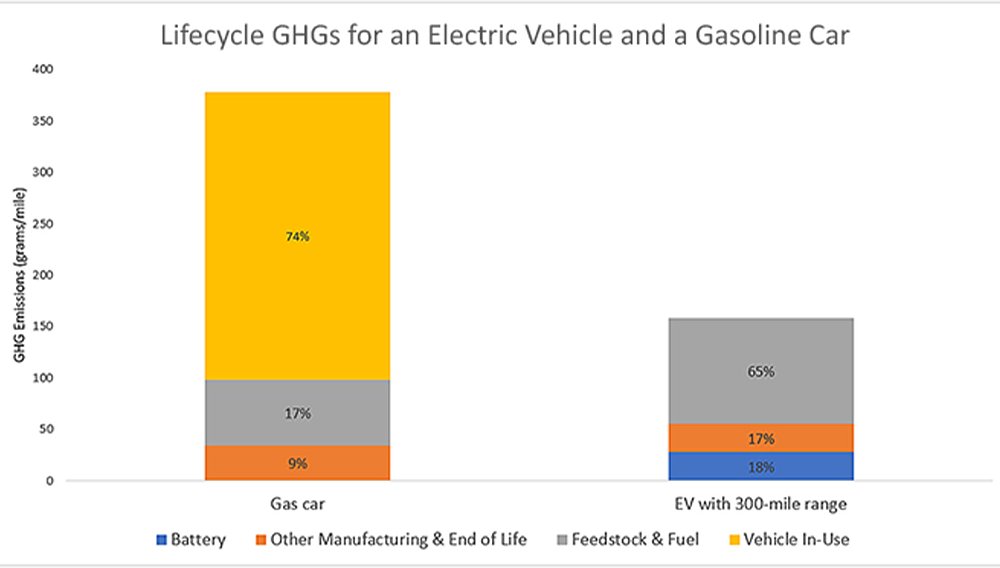

Electric vehicles benefit the environment by producing less lifetime greenhouse gas emissions than internal-combustion vehicles, but they do raise new environmental issues of their own. A joint study published by the University of California, Davis and The Climate and Community Project (CCP) focuses on the environmental damage of lithium mining and the inability to meet future demand, if dependence on electric vehicles increases as projected.

But before opponents of electric vehicles seize on that statement and say EVs are worse for the environment than ICE-powered vehicles, that's not what the researchers are saying. And it's possible that motorcycles can be part of the solution to the problems they raise.

Titled “Achieving Zero Emissions with More Mobility and Less Mining,” the 74-page report still makes it abundantly clear that shifting away from fossil fuels is imperative to reduce greenhouse gas emissions. In the United States, the transportation sector is the leading source of greenhouse gas emissions, accounting for 28% of the nation’s carbon footprint. It also remains the only sector where emissions continue to climb. The most common policy approach is to push private vehicle owners to transition to electric models, but the problem with that, the study notes, is meeting the demand for lithium for the batteries needed to power that electric future. In part, the problem in the United States is a typically American one: Things keep getting bigger.

Growing pains

When Nissan Leaf debuted in 2010, the all-electric model featured a 24 kWh lithium-ion battery. By the turn of the decade, batteries ballooned in size. Global EV capacity averaged just over 40 kWh in 2021. That number soared to 70 kWh in the United States, where consumers demand vehicles that can cover vast distances. Mind you, that’s just the median figure. New electric trucks keep getting bigger batteries and, at the extreme, the 2023 GMC Hummer EV SUT dwarfs all competitors with its 205 kWh battery. This lithium-ion arms race isn’t exclusive to four-wheeled vehicles, either.

In 2009, the Zero DS drew power from a 4 kWh battery. The brand’s latest model and first adventurer-tourer, the DSR/X, boasts a massive 17.3 kWh battery pack. Zero’s optional Power Tank upgrade only boosts the e-ADV to a 21-kWh capacity. Yet, the DSX/R’s direct competitor, the Energica Experia, comes with a 22.5 kWh power pack in stock form.

Compared to automotive options, electric motorcycle batteries remain relatively compact. At the same time, the Zero DSR/X and Energica Experia now rival the 2010 Nissan Leaf’s 24-kWh capacity. Ever-rising battery volumes don’t just result in EVs of portly proportions, though, they also intensify lithium mining worldwide.

The snowball effect

As the 33rd most common element on Earth, lithium is both abundant and widespread. You can find the highly conductive compound in everything from psychiatric medicine to ceramics, but rechargeable battery production commands approximately two-thirds of today’s lithium supply. Untapped global resources amount to 89 million metric tons, with 22 million metric tons in reserve. Yet, when researchers forecast EV demand to 2050, “the US EV market alone would require triple the amount of lithium currently produced for the entire global market.”

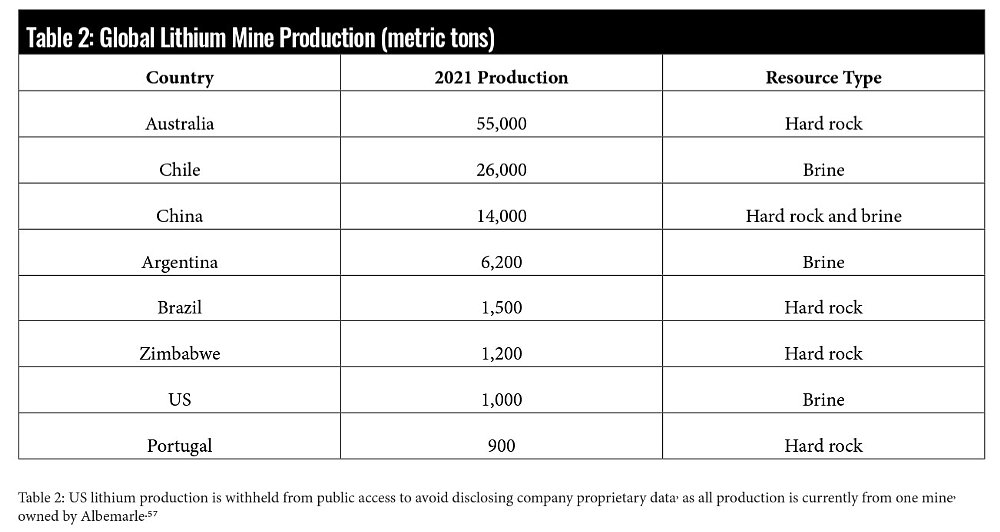

Just four countries — Australia, Chile, China, and Argentina — control 95% of today’s global lithium production. In 2021, the United States only contributed 1,000 metric tons to the 105,800 metric tons processed worldwide. That’s merely a drop in the lithium mining bucket. Predictably, the United States aims to improve that standing in the coming years. For proof, look no further than the state of Nevada, which has up to 50 lithium extraction projects currently under development.

Even so, the latest projections indicate that lithium mining operations will need to increase by 200% in order to meet EV demand in 2035. That statistic wouldn’t seem as ominous if lithium extraction wasn’t so detrimental to local ecosystems. Two lithium mining processes dominate the field today: hard rock extraction and brine extraction.

Hard rock extraction involves dissolving mined ores with sulphuric acid, leaving behind lithium for collecting. This method yields higher concentrations of the metal but it’s also costly, emits more CO2, and requires more freshwater resources. Even after acid processing, hard rock extraction produces significant waste tailings, further impacting the environment.

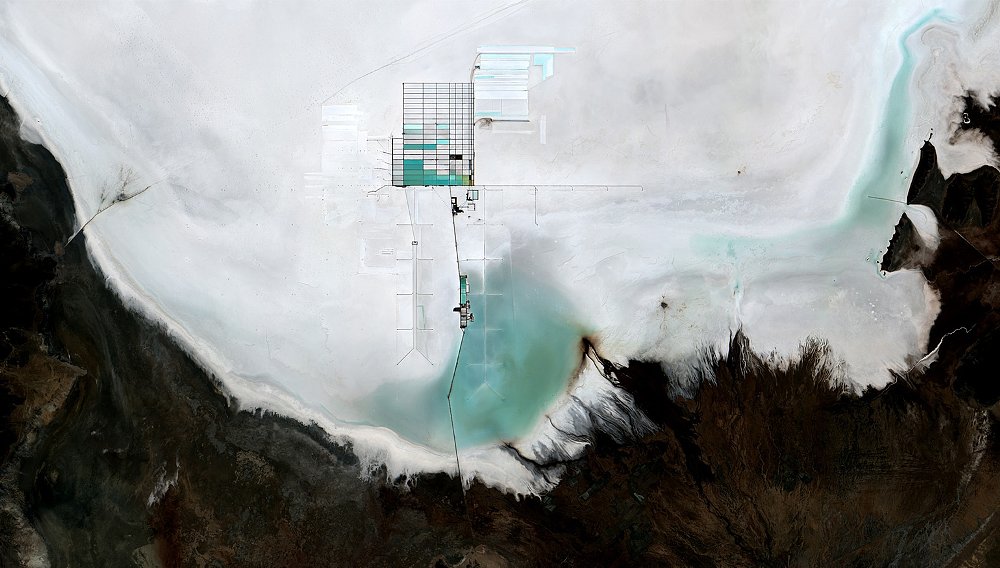

Brine extraction requires pumping brine from underground aquifers into large pools. The solution evaporates under the sun for around a year before the lithium reaches the desired 6% concentration. The procedure isn’t without its hazardous byproducts either. Brine extraction not only leaves behind toxic chemicals and waste salts, but also depletes local freshwater stores.

Making matters worse, lithium mines are often located in water-stressed regions. The water-intensive and water-contaminating practices only place additional strain on the ecosystem. Many mining operations affect the cultural landscape, as well, with sites encroaching on indigenous populations in the United States, Chile, Argentina, and Portugal. Despite all those detractions, researchers still hold out hope for the future.

A new hope

Given the latest data, researchers call for reducing car dependence, regulating EV battery sizes, and promoting lithium recycling. According to the study, this model could reduce lithium demand by up to 66%. That solution seems simple in theory, but it’s much more challenging in practice. Currently, lithium is cheaper to mine than it is to recycle. Plus, even if recyclers collected 100% of retired EVs by the year 2050, the recovered material wouldn’t meet 50% of the lithium demand.

For that reason, mitigating both car dependence and battery sizes is critical to the future of transportation. While the study envisions a future where public transit and active transportation limit our reliance on personal cars, researchers are forgetting one alternative: two-wheeled vehicles.

Researchers often point to Paris as an example, where car use has reduced by 30% in recent years. What the study doesn’t expound upon is how much motorcycle, scooter, and electric bicycle ownership influences those figures. The onus isn’t on the public alone, though. Suppliers are also instrumental in the shift away from fossil fuels.

In Taiwan, electric scooter brand Gogoro established its GoStation swappable battery network in 2015. Today, the company claims that it performs around 390,000 daily swaps. Gachaco, a battery-swapping company established by Honda, Kawasaki, Suzuki, Yamaha, and ENEOS, recently opened two locations in Japan. In India, Honda also kicked off its battery-sharing services for electric tricycle taxis. These are not the massive batteries found in cars, but rather batteries small enough to be easily removed and replaced by hand.

Manufacturers continue to seek alternatives as well. Yamaha recently partnered with Toyota to develop hydrogen-powered engines. Japan’s Big Four also formed the Hydrogen Small Mobility and Engine Technology (HySE) pact to jointly develop hydrogen-powered motorcycles. Kawasaki even unveiled several alternative-fuel models at EICMA 2022, including a Hybrid EV featuring an “internal combustion engine and electric motive power.”

If the University of California (Davis) study shows us anything, it’s that there’s no panacea for petrol. From electric to hydrogen, from public transit to personal vehicles, we will need to diversify our means of transport in the future. Incentive programs, infrastructure projects, and public sentiment will drive that transition. But since part of the problem is that bigger and bigger batteries require more and more lithium, then motorcycles, which can run on smaller batteries, should be considered as part of the solution.

Membership

Membership