The trend of hipster bike videos has sort of come and gone, but everyone remembers the formula well: Garage opens to light, closeup of some ridiculously old appliance (AM radio or maybe coffee maker) in use, then eventually we see sparks being thrown as a lovely rack focus leaves us with grinding wheel bokeh.

That’s all swell, and I personally use the shit out of my angle grinder, but most often the tools I reach for when fabricating or building are hand tools. I have a few faves, and I think of some of them like familiar friends. I believe very heartily in buying the best tools you can if you use them often but some of my best little shop buddies have the humblest costs attached to them.

Here are a few pieces I reach for often. I thought I’d put some of my unsung buddies on display.

Countersink

I find myself using countersinks most frequently for cleaning up holes. A nice chamfer usually helps debur any chips left from the drill and often helps speed assembly, both initially as well as years down the road. It’s easy enough to swap the drill bit for a countersink in the chuck of the drill press. And for those times I’m cleaning up a hole in a material where using a power tool is not desirable or possible, popping the bit into a handheld holder allows me to clean up errant swarf that hasn’t yet broken free of the workpiece.

Automatic center punch

Have you ever attempted to drill a hole on a workpiece and experienced either deflection of the drill bit or, worse yet, the drill bit “walking” on the smooth surface, rather than plunging directly into it? If so, odds are good you didn’t use a center punch. By creating a tiny pocket with a punch, the drill bit’s propensity to wander is greatly reduced. An automatic center punch, unlike a standard center punch, doesn’t require a hammer stroke to make the indent. Instead, it’s a spring-loaded affair that can be operated with one hand. Locate, press, drill… with no finish damage from a wandering drill bit. Once you use one, you’ll wonder how you got along without one.

Files

I’m lumping all my files together here. (There are quite a few types!) From aggressive metal removal to barely kissing material off the workpiece, files allow the user to shape metal with a degree of control that’s simply unmatched by powered tools. (Don’t believe me? Watch this guy use his files. Note the fit of his pieces.)

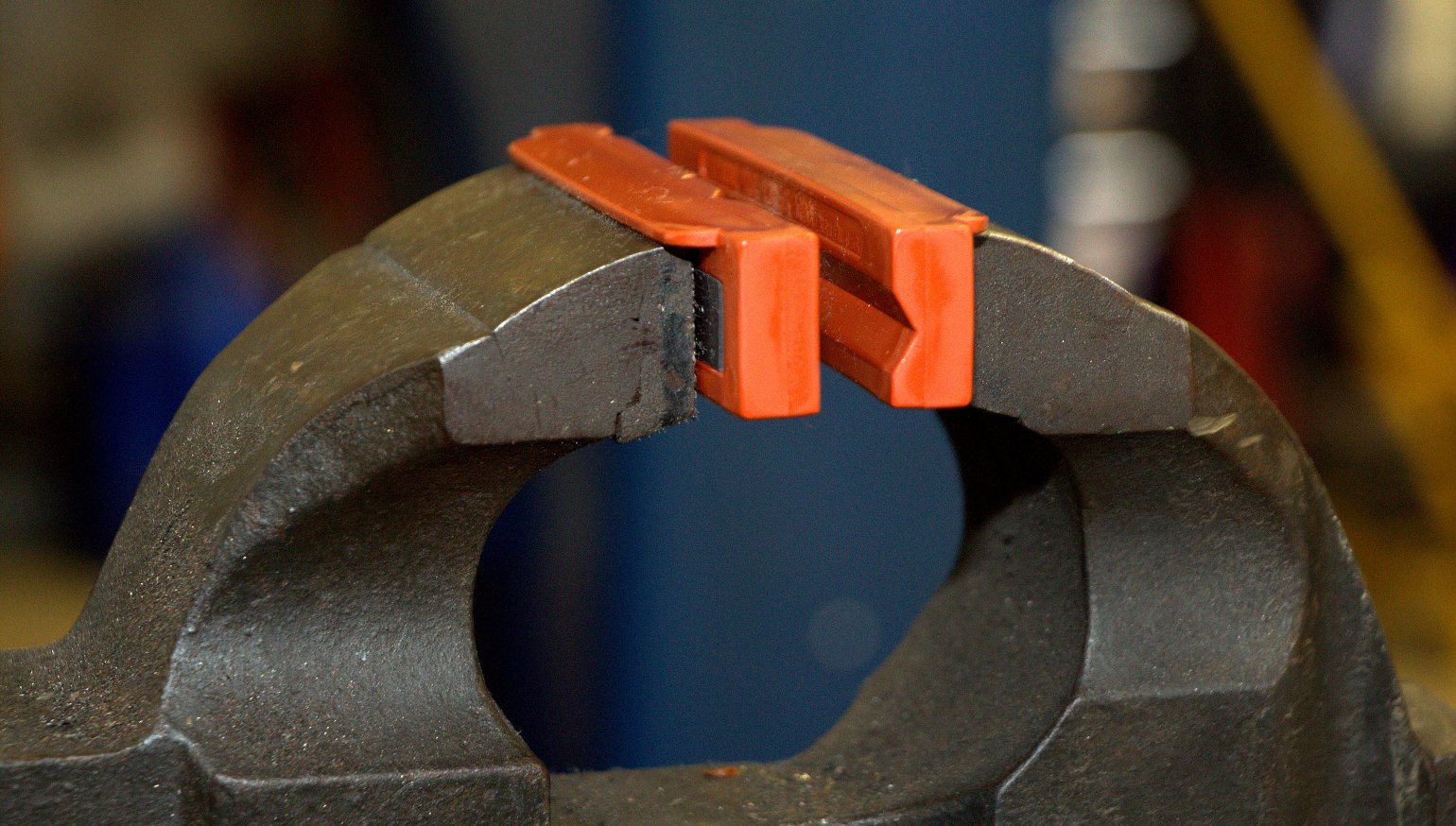

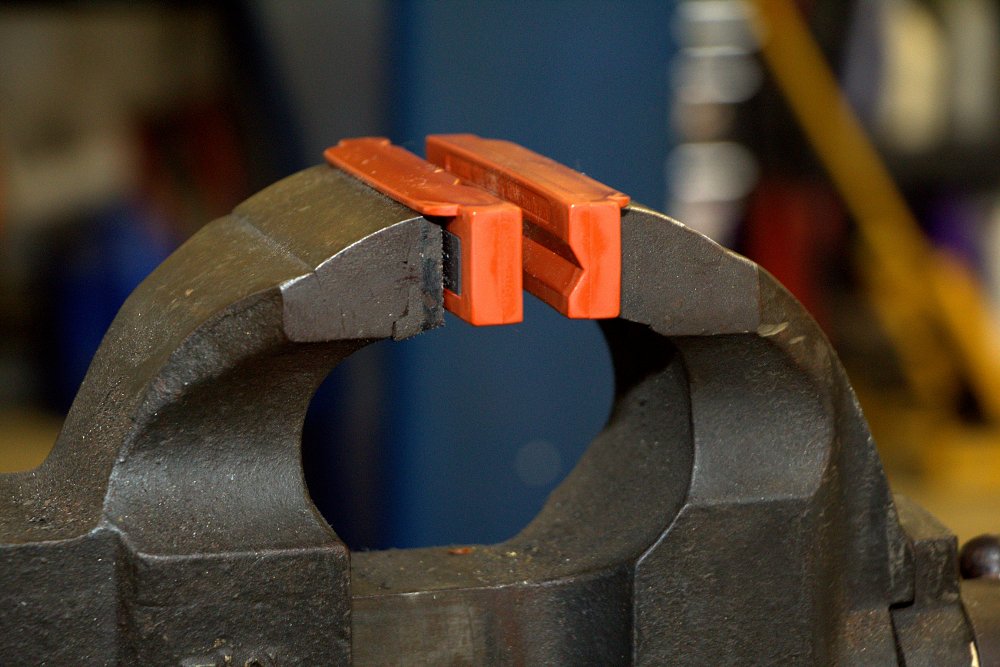

Vise

A good friend of mine found out I had no vise. This was way farther along in my fabrication and repair career than I'd care to admit. He was so baffled as to how I could work that he dug one out of his stash and left it out until the next time he saw me. Having had one in previous shops, I was giddy. I use my vise for so many holding tasks. I often use it as a fixture for welding. Obviously they can be used to hold a workpiece. They’re wonderful for assembling things; it’s like having a shop helper or extra set of hands. They can even be used more creatively than that; I have a jig I built for working on Harley four-speeds that works a treat. No more chasing it all over the bench as I attempt to snug things up. And with a set or two of soft jaws, items like fork rebuilds become so much easier you’ll wonder how you ever worked without a vise.

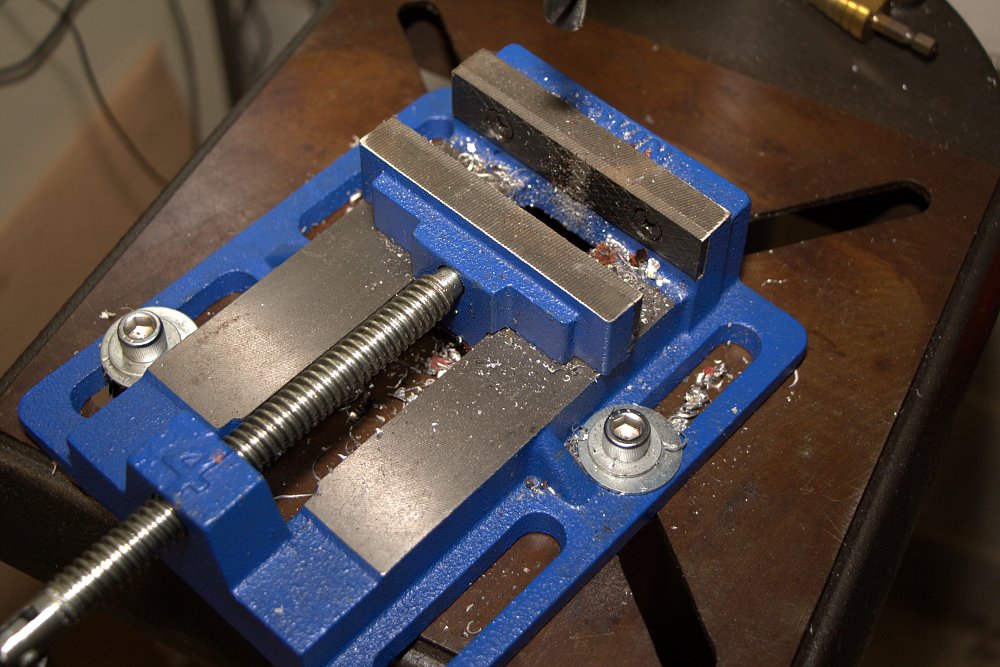

My second vise is actually a drill-press vise. If you have a good drill press, a vise for the table is essential. One of these days I’ll upgrade to a cross-slide vise so I can work a little quicker, but for the time being, the drill press vise is good enough. Having a vise on the drill press becomes more and more essential the bigger your drill press is. It not only steadies the workpiece for greater accuracy, but it also protects you (and the pretty bikes you may have parked nearby). If you want to visit the hospital or throw a scare into yourself, try to hold something in your hands when using a powerful drill press. There’s nothing like a valuable or heavy part being hurled at high speed across the shop to remind you you’re not being safe.

And if any of you are planning on going shopping, you can find great vises at most flea markets for junk money. If you're the "Can I get free shipping with Prime" type, one of our readers turned me on to this baby, which is neat. Not only can you use it on your truck for field work, but with the bench mount, the vise can be rotated 90 degrees. That’s super sweet for doing fork leg work! (Thanks to reader serizawa for the mention.)

Vises have great potential for misuse, but they are almost a cornerstone of some shops. This is not accidental.

Tip cleaner/guitar strings

The tip cleaner was suggested by New Guy Greaser, and I’m all for it. Originally developed for cleaning the fine passages in torch tips, tip cleaners are cheap enough to have a few handy. I use mine for cleaning my torches, obviously, but Andy uses one for unplugging carburetor jets and clearing fouled brake bleed nipples.

I play guitar, so after I install a set of freshies, I normally clip the ball ends and the tunin’ peg ends off, and save them for the same purpose. Those also make great fish wires for running wiring internally on frames and bars.

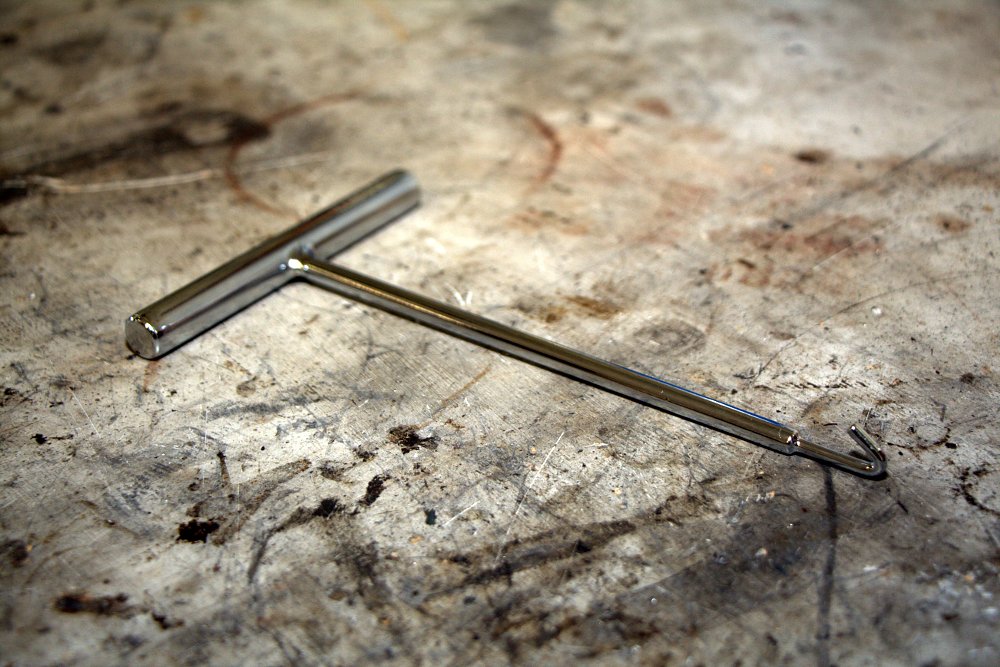

Exhaust spring puller

Man, am I ever glad I got one of these. I use mine for its intended purpose, installing slip-on pipe springs, but I’ve used them for lots of other tasks. They’re great for pulling dB killers from the very same pipes that I just installed! They are also supremely useful for other springs. (Harley brake pedal and jiffy stand springs can be seemingly impossible to install when they’re in place on the motorcycle.) I also use them to yank the R-clips on bikes that use them to retain sprung seats. And finally, they can be helpful for pulling seals once started. Fork tubes and Harley clutch hub nut seals come to mind.

Torch

Allthread

Allthread is simply a trade name for threaded rod. I use this for a variety of purposes. First, it can be helpful for mocking up something before you start cutting down material. For instance, when fabricating shift and brake linkages, a piece of all thread and a few heim joints can save the hassle of making a piece that’s too long or too short or threaded incorrectly.

Mostly, though, I use Allthread with some washers, spacers, and nuts as a puller or press for items that can’t be put into a shop press. I’ve used small pieces to install bushings in Harley tankshift transmission tops, and I’ve used much, much larger pieces to install neck bearing cups in frames — and they can also be used to put the races into the neck cups once they’re in.

If you don’t have a shop press, get yourself a little supply of Allthread and some fasteners, or simply buy as you need.

This list is by no means comprehensive, but these items are all pretty affordable, so if you have the standard toolbox and want to seriously boost your shop time and make better use of your time with the tools, try ‘em out if you don’t own ‘em already.

Membership

Membership